-

sales@plasmainduction.com -

08048778299 - Send SMS

- Send Email

- GST No. 24AANFP1676L1ZR

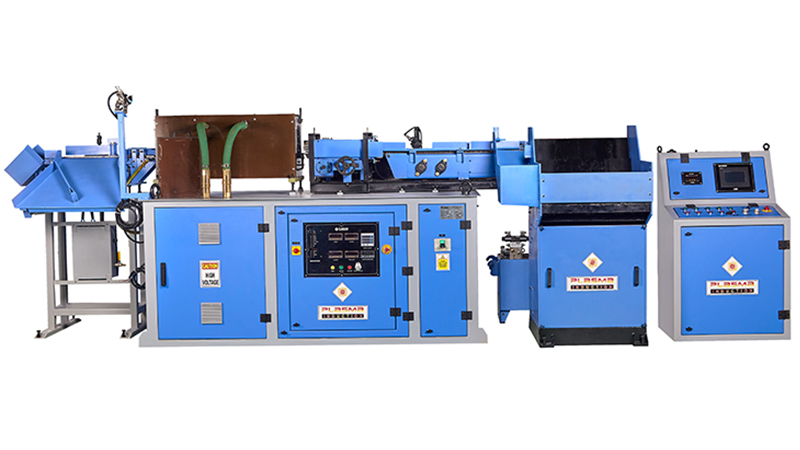

Heating Furnace

Leading Manufacturers, Exporters, Wholesaler and Retailer of G-25/G-30 Heating Furnace, G-5/G-10/G-20 Heating Furnace and G-50 Heating Furnace from Gandhinagar.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Material | Metal |

| Use | Annealing, Curing, Stretch Leaving, Temperature Control |

| Application | Automobile Industries |

| Feature | Digital Display, Energy Regulator, Pyrometer, Thermocouple |

| Voltage | 110V, 220V, 380V |

| Condition | New |

| Power Source | Electric |

| Warranty | 2 Year |

Preferred Buyer From

| Location | Worldwide |

100% 6th Generation IGBT based series resonant power topology-based induction heater. Accessories of Automatic billet feeding system, Automatic heavy-duty elevator, Infrared non-contact pyrometer, 2 way /3 way accept reject system. Safety interlock with feature of exceptionally superior performance,loss motion detection,standby & rapid start/stop,energy monitoring system,epoxy insulated coil winding.

Product Specification

Power Rating: 125 KW TO 300KW

Frequency: 3 KHZ to 20 KHZ

Size: 1 Mtr X 2 Mtr X 1.2 Mtr

Automation: Optional with touch screen.

Loading System: Pneumatic / Hydraulic Pusher / Infeed drive.

Water System: separate with Alfa Laval Heat Exchanger.

Application

-

Forging Industries

-

Auto Component manufacturing

-

Engineering Parts manufacturing

-

Agriculture parts manufacturing

Accessories

- Hydraulic Pusher System

- In Feed Tractor Drive

- Automatic Billet Feeding System

- Automatic Heavy Duty Elevator

- Pyrometer

- 3 Way Accept/reject System

Safety Interlock with Feature

- Exceptionally Superior Performance

- Loss Motion Detection

- Standby & Rapid Start/stop

- Energy Monitoring System

- Epoxy Insulated Coil Winding

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Material | Metal |

| Use | Annealing, Curing, Industrial, Stretch Leaving, Temperature Control |

| Application | Automobile Industries |

| Feature | Digital Display, Energy Regulator, Pyrometer, Temperature Control, Thermocouple |

| Voltage | 110V, 220V, 380V |

| Condition | New |

| Power Source | Electric |

| Warranty | 2 Year |

Preferred Buyer From

| Location | Worldwide |

Fully IGBT based Induction Heater with Voltage inverter series topology. And it’s Give a better productivity. It’s consist of Plate Type (Alfa Laval) Heat Exchanger with Water Pump (S.S. Body) along with valves. Safety Interlocks.Special Feature of Unity power factor, Negligible Scale loss, Uniformity Control,Compact Modular Design, 2.75kg / KW productivity.

Product Specification

Power Rating: 40KW TO 100KW

Frequency: 3 KHZ to 50 KHZ

Size: 1 Mtr X 1.5 Mtr X 1.5 Mtr

Automation: Optional

Loading System: Manual / Pneumatic Pusher

Water System: Inbuilt on single Platform.

Application

-

Forging Industries

-

Auto Component manufacturing

-

Fasteners manufacturing

-

Engineering Parts manufacturing

Accessories

- Vibro Feeder

- Pyrometer

- Accept/reject

- Elevator

- Pneumatic Pusher System

Safety Interlock with Feature

- Negligible Scale Loss

- True Temperature Uniformity Control

- Compact Modular Design

- Water Temperature & Pressure Interlock

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Material | Metal |

| Use | Annealing, Curing, Industrial, Stretch Leaving, Temperature Control |

| Application | Automobile Industries |

| Feature | Digital Display, Energy Regulator, Pyrometer, Temperature Control, Thermocouple |

| Voltage | 110V, 220V, 380V |

| Condition | New |

| Power Source | Electric |

| Warranty | 2 Year |

Preferred Buyer From

| Location | Worldwide |

100% 6th Generation IGBT based series resonant power topology-based induction heater. Accessories of stepper feeder with bin tipper, conveyor with hydraulic pusher (stacker), coil shutter mechanism,heavy duty in feed conveyor with tractor drive,pneumatic grabber system, non-contact infrared pyrometer, and 3ways accept/reject system.

Product Specification

Power Rating: 300KW TO 2000KW

Frequency: 3 KHZ to 6 KHZ

Size: 1.2 Mtr X 3.5 Mtr X 1.2 Mtr

Automation: Optional with touch screen.

Loading System: Stacker mechanism/ Stepper Feeder.

Water System: separate with Alfa Laval Heat Exchanger.

Application

-

Forging Industries

-

Auto Component manufacturing

Accessories

- Stepper Feeder with Bin Tipper

- Conveyor with Hydraulic Pusher (stacker)

- Coil Shutter Mechanism

- Heavy Duty in Feed Conveyor with Tractor Drive

- Pneumatic Grabber System

- Pyrometer

- 3 Way Accept/reject System

Safety Interlock with Feature

- Higher Efficiency with 6th Generation Voltage Fed Topology

- Line Isolation for Better Safety & Coil Performance

- Scada System with Recopies

- Pyrometer Monitoring to Better Quality Production